The system is divided into three heating zones to ensure optimum medium processing. The medium melts progressively as it passes through the zones of increasing temperature. Once it has reached the dispensing area, the medium is at the perfect temperature. This careful processing is further improved by the optional use of a desiccant cartridge to reduce contact with humidity.

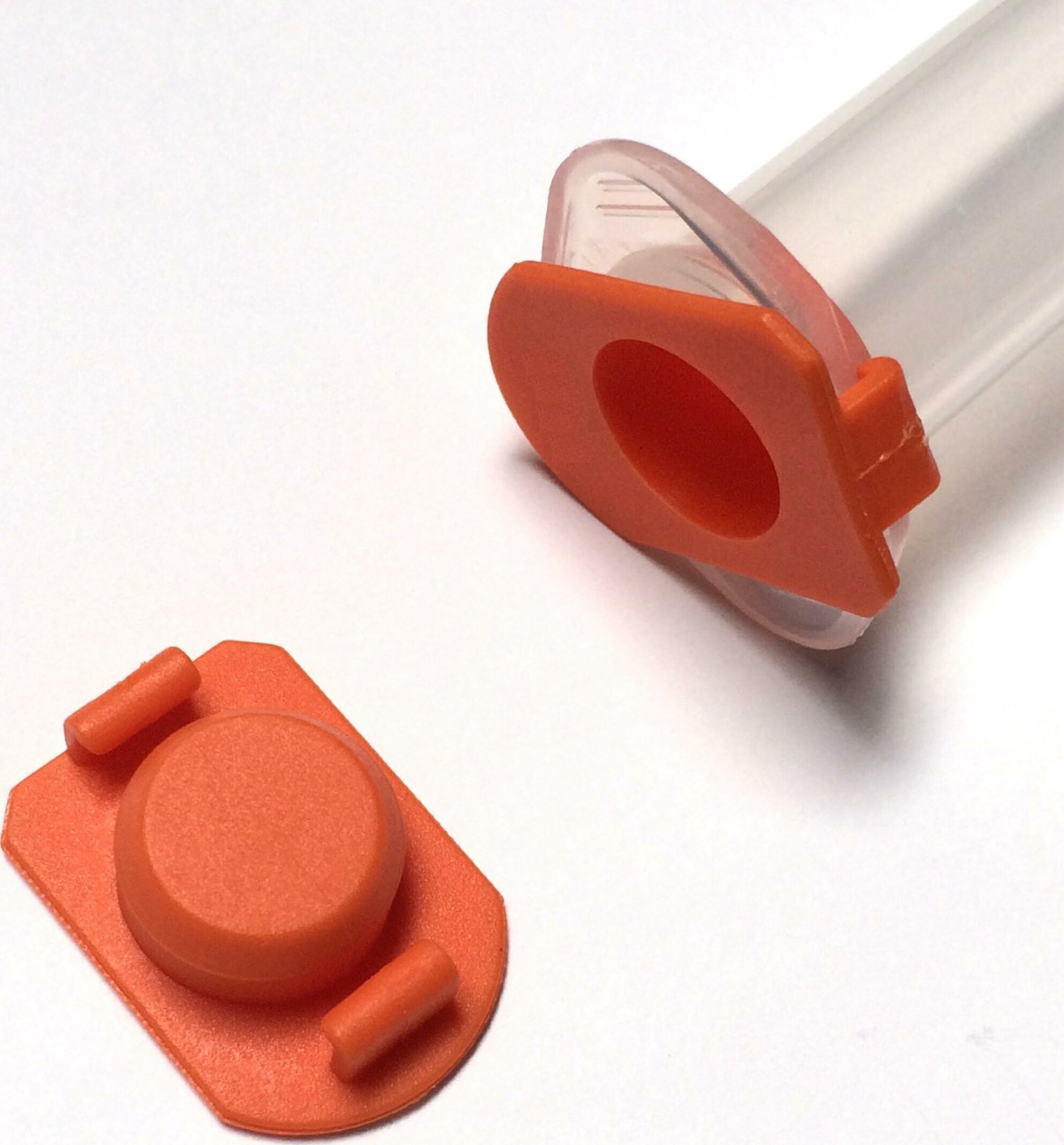

The media tank is fitted with an ultrasound based level measurement system which can determine both level and melting state of the medium. These features ensure high process reliability. The Polyurethane Hot-melt system is a modular system. This modular design has a crucial advantage: all parts which are in contact with the medium can be removed, cleaned or replaced individually.

The modular dispensing valve can be operated with a continuous dispensing frequency of up to 500 Hz to allow for high path speed when dispensing hot melt media, achieving line widths or dot diameters of 0.3 mm, depending on the adhesive.

The Polyurethane Hot melt system is suited for applications in the field of electronics manufacturing.